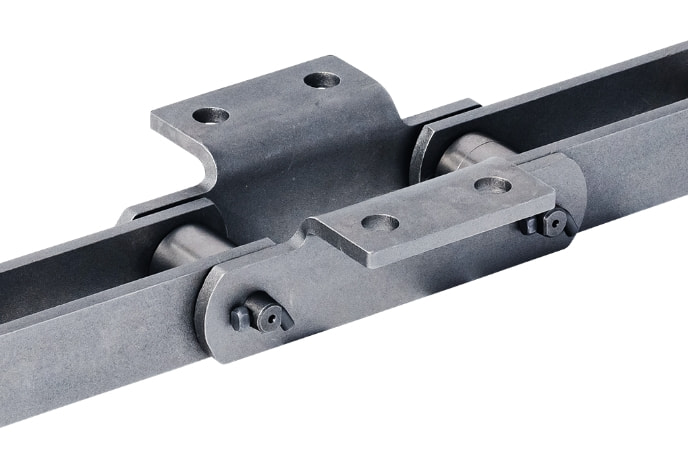

Custom-made chains

We can create custom-made chains to meet

various requirements.Proposal to solve customer’s problems

Our goal is to make our clients feel that

“ZEXUS CHAIN will certainly provide solutions.”

Proposals for suitable combination of components to your environment.

There are a wide variety of chains in terms of type, purpose, performance, specifications, shape, and usage environment. It is very difficult to find the best one from such a large number of items! We emphasize “custom-made” services, in which we design, propose, and manufacture chains that meet the customer’s requirements.

Please contact us for any kind of consultation regarding chains!

- Applications

- Longer life

- Shape

- Strength

- Abrasion

resistance - Environmental

resistance - Eco-friendly

- Other

requirements

We produce excellent chains

that have never seen before.We want to create something new.

Our primary focus is the needs of our customers. That’s why we begin with in-depth communication with our customers. Sometimes the functionality they need is not available in existing chain. In such cases, we ask about their equipment and environment to gain a deep understanding of their requirements. And then to provide optimal products, we design, propose manufacture the chains. We’re always thinking of providing the best chain based on all possibilities and challenging to create something new.

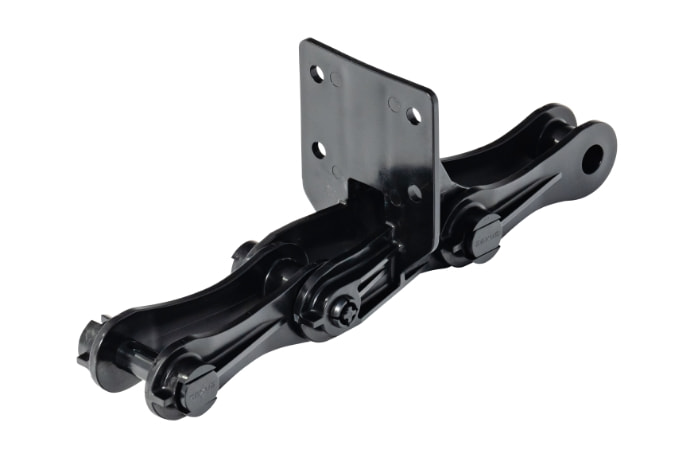

At low cost,

we offer small-lot production Reducing manufacturing costs through unique innovations

Most of the orders we receive are for custom-made, multi-product small-lot production. Although there are some concerns regarding higher unit prices for small-lot manufacturing services, we aim to reduce manufacturing costs through unique innovations such using common parts. In order to provide our customers with chains they can rely on, we are constantly striving to optimize not only quality, but also prices.

For example, we can respond to the following requests:

- Want chains used in food factories, we don’t focus on functionality but also food hygiene and safety.

- Want chains with shock resistance for equipments subjected to shock loads.

- Want corrosion resistant chain for equipments in corrosive environments.

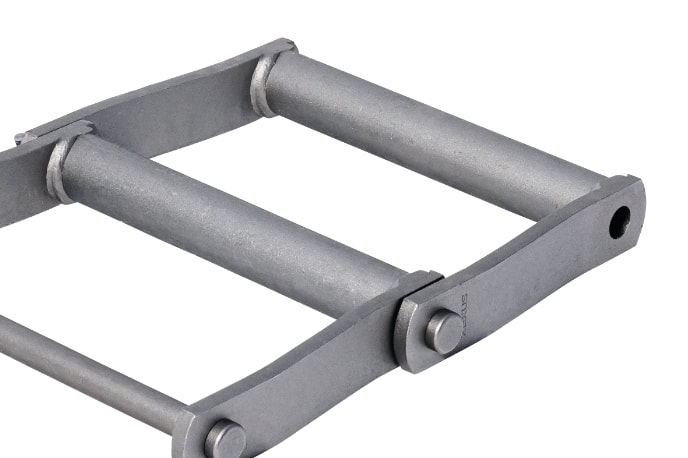

Featured Products

For extended and reliable useSatisfactory durability for operation and maintenance

Thankfully, many of our clients continue to use our products, and one of the reasons is the high degree of customer’s satisfaction. Based on the close and deep communication with customers, we take into consideration the usage conditions and select the optimal specifications and provide meticulous support to ensure long and reliable use.

Proposed the most suitable chain based on the data from the inspection in selecting a replacement during the periodic maintenance.

Chains are consumable items, and periodic inspection surveys are essential. We inspect and investigate chains and proposes chain repair or replacement as necessary. In one case, based on our investigation report, we proposed and delivered an optimal chain, while taking into consideration the condition of the existing chain and the operating environment.

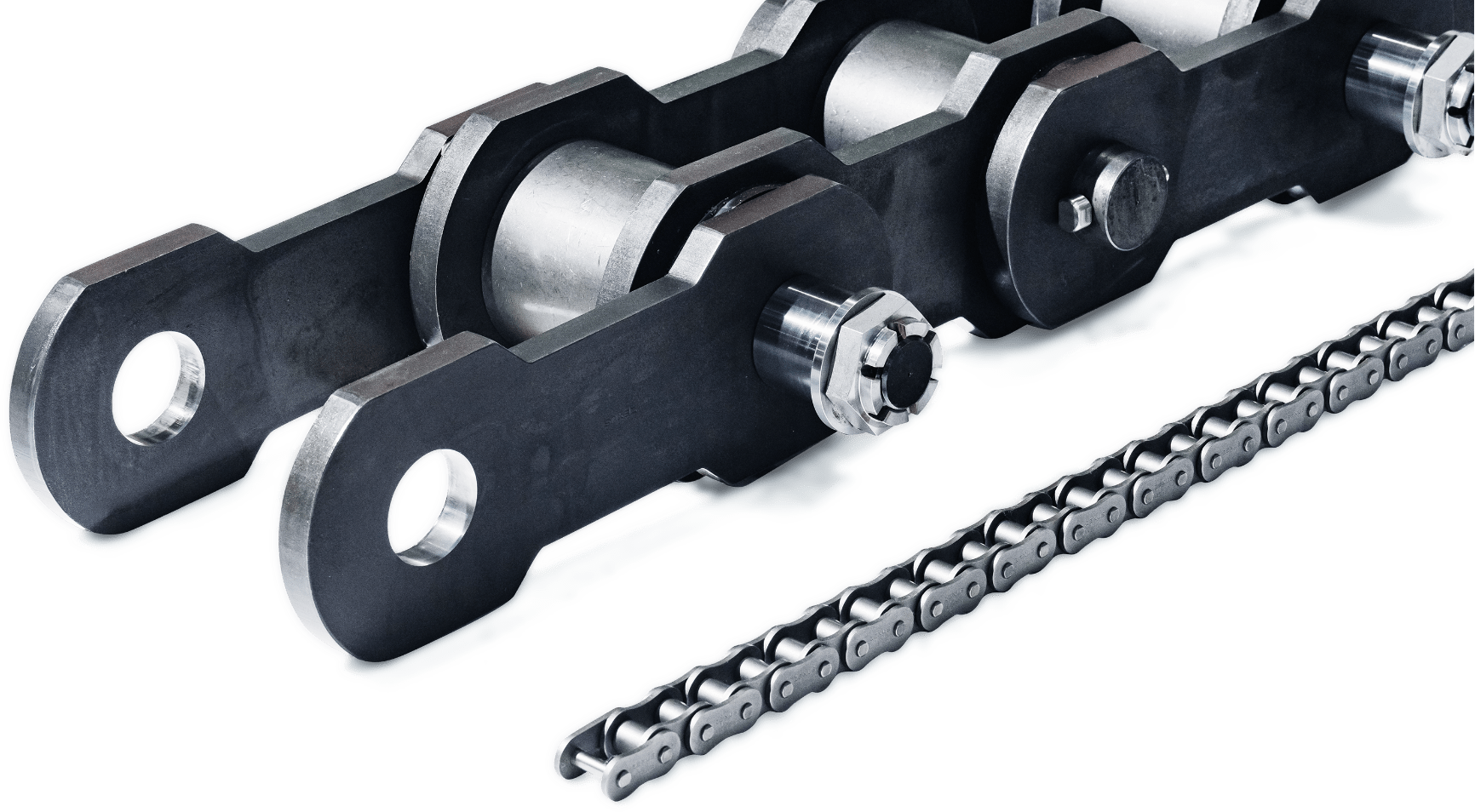

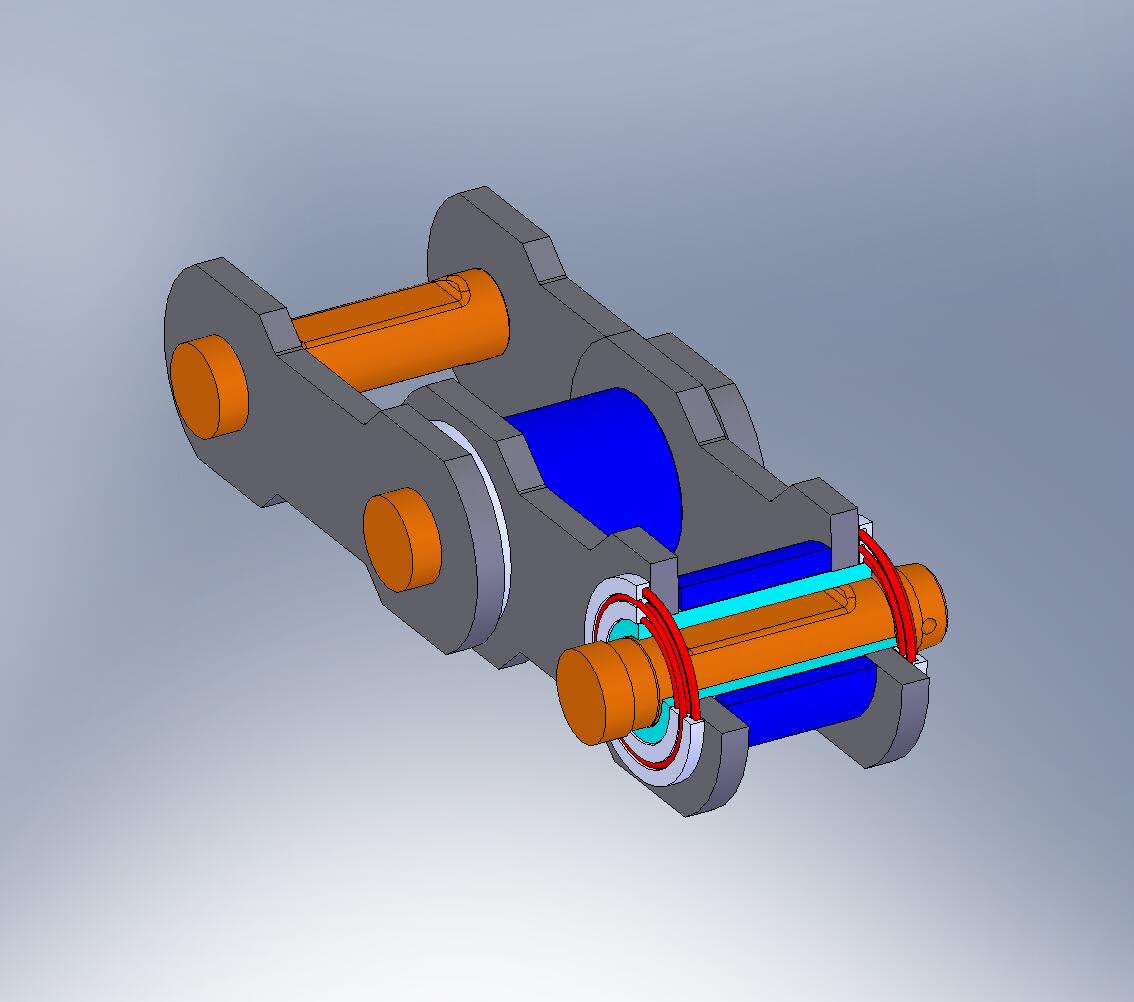

ECO-Friendly “Oil Sealed Unloader Chains”

Steel plants have facilities that handle large cargoes on their wharves, and one such facility is a continuous ship unloader that unloads iron ore and other raw materials from ships. Although continuous ship unloaders use chains for unloading, conventional chains require periodic lubrication wherein each time the equipment must be shut down, In addition, there was an environmental issue due to oil splashing in the surrounding area. Our Oil-Sealed Unloader Chain impregnates and seals lubricant, thereby eliminating the need for the periodic lubrication, which has the added benefit of improving productivity, saving lubricants and preventing oil splashing.

Inquiry to maintenance for custom-made chains

- 01Inquiry and consultation

- According to your request, we will inquire about the necessary information for manufacturing chains, such as the intended use, usage environment, purpose of use, and quantity.

Examples of consultation:

- Want to improve existing chains.

- Look for chains

used in new equipment. - Look for chains

used in renovated equipment.

We will visit your site and conduct an on-site survey and analysis as necessary.

- 02Proposal and design

- We analyze and identify essential issues and select appropriate chains.

While exchanging opinions with each customer, we determine specifications and design improvements after examining the parts and chain structure of the product that requires improvement. - 03Manufacturing

- Based on our accumulated know-how, we manufacture products in Japan emphasizing on quality, cost, and delivery time.

- 04Delivery

- We ensure delivery by the date and delivery method designated by the customer.

- 05Support & Maintenance

- We perform inspections according to usage conditions.