About Us

Based on the knowledge and expertise

accumulated over more than 100 years, we are

confident in our ability to develop and respond

to any situation.

01Our Position in the industry

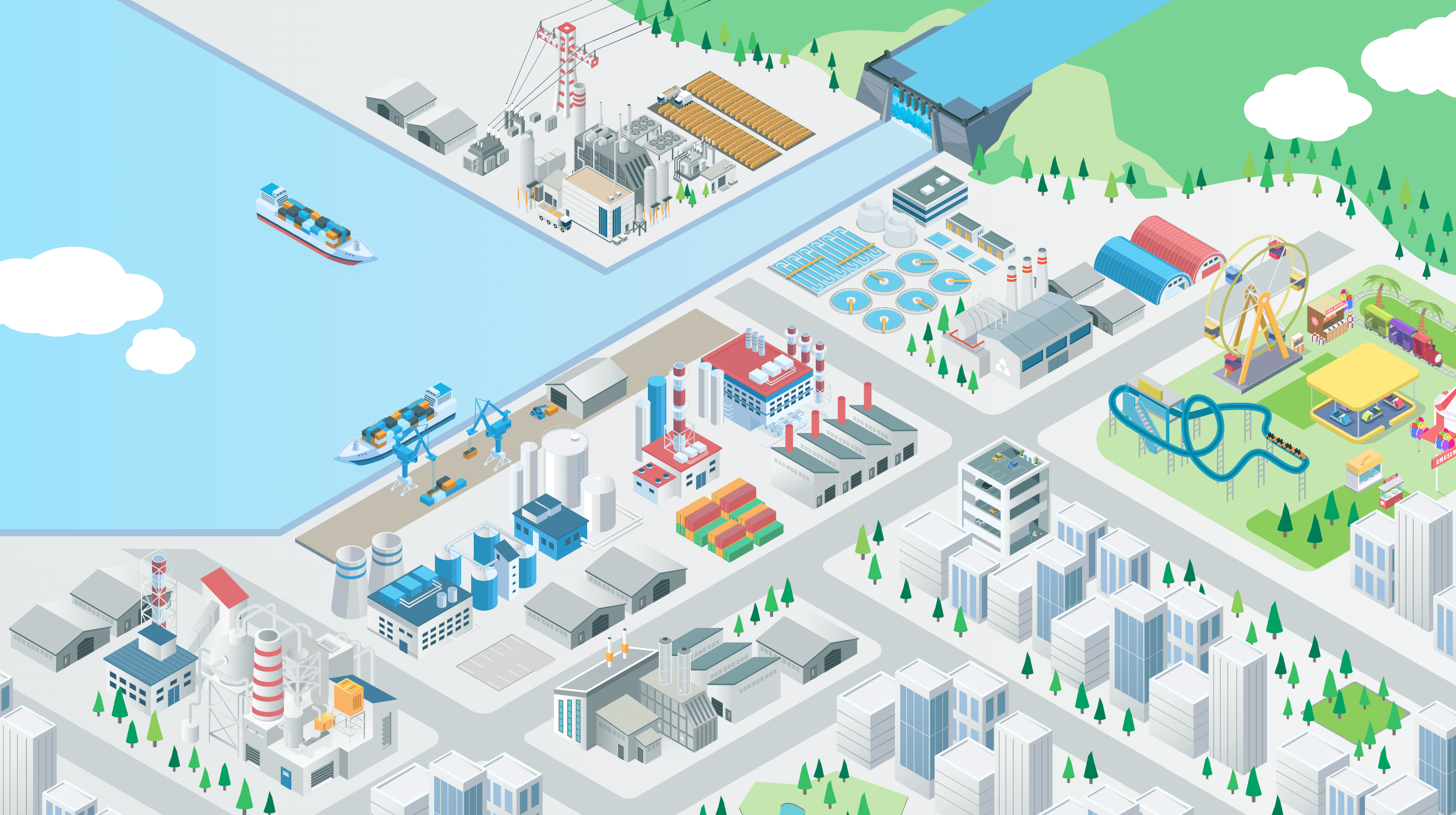

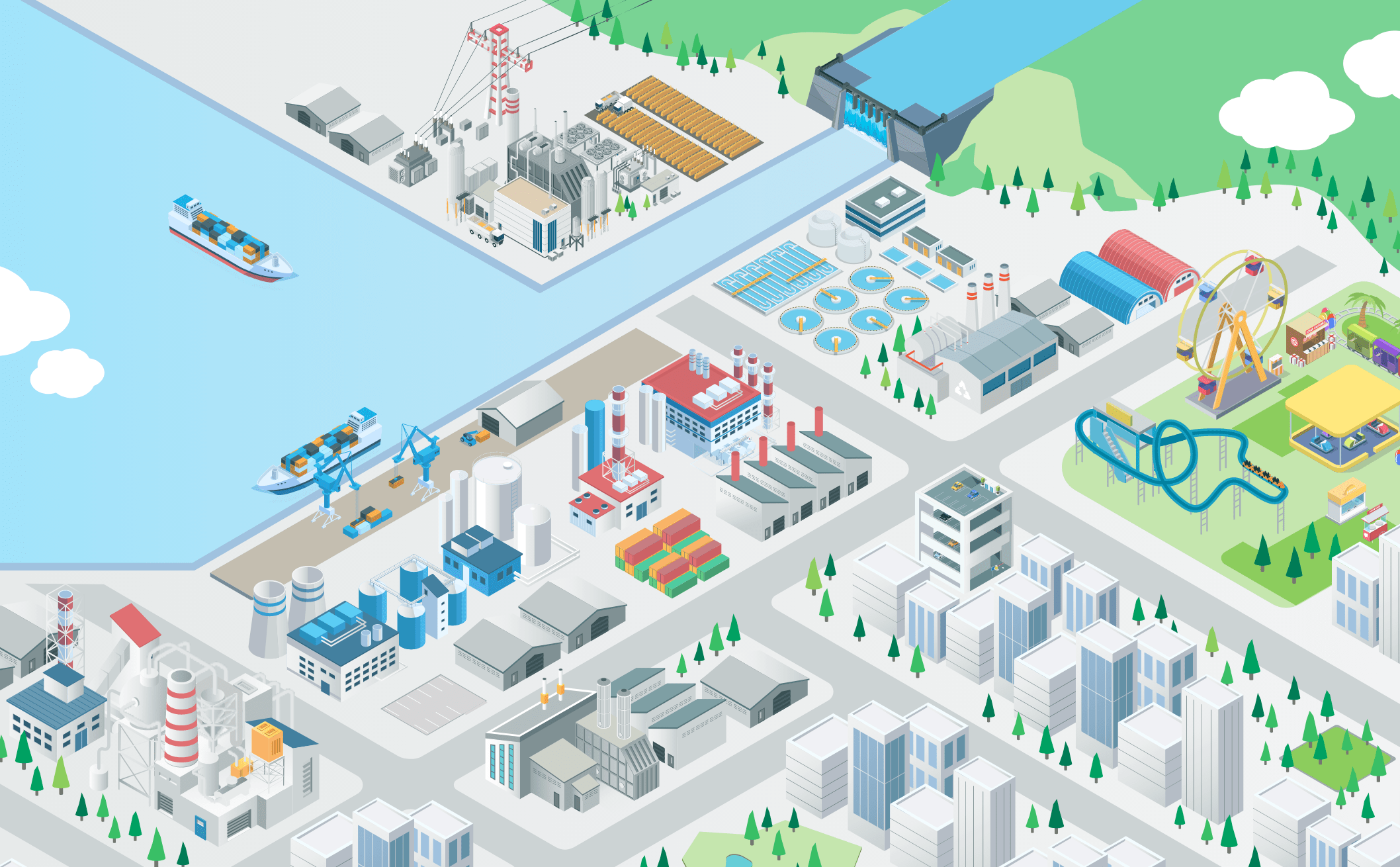

We develop and manufacture industrial chains sustaining a prosperous society and industry.

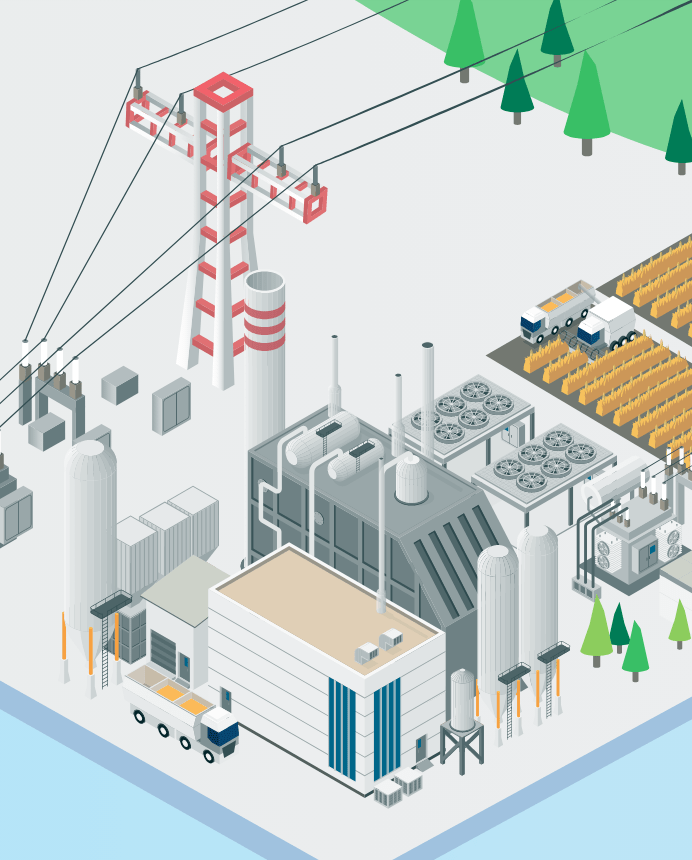

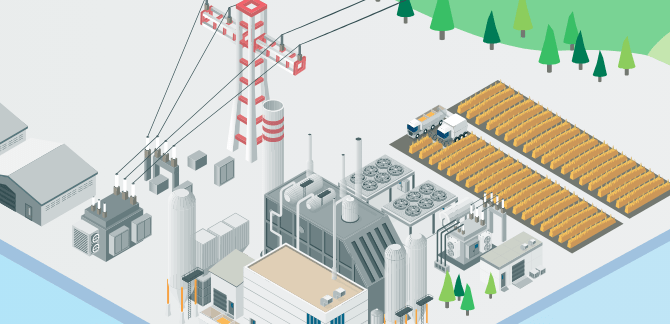

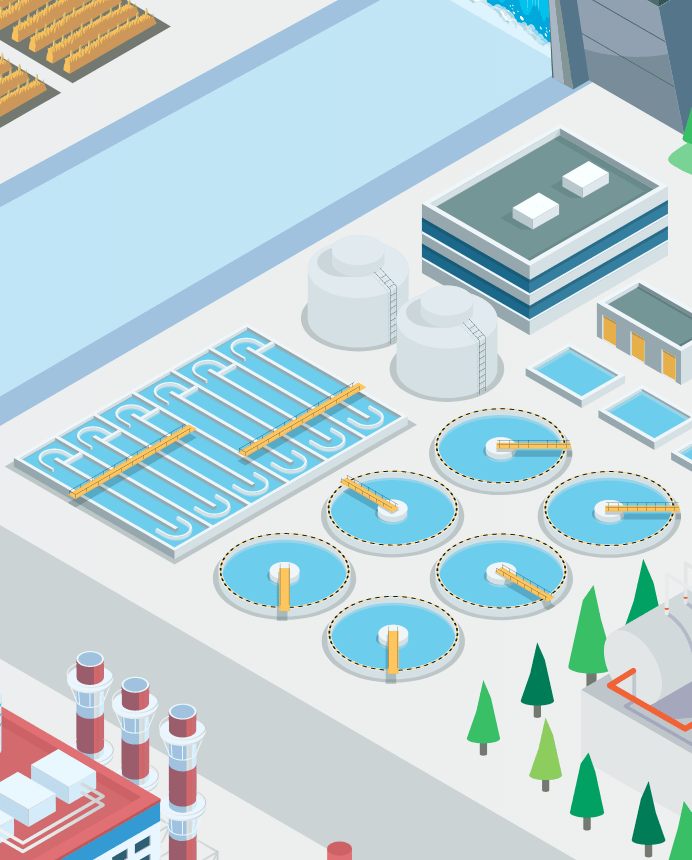

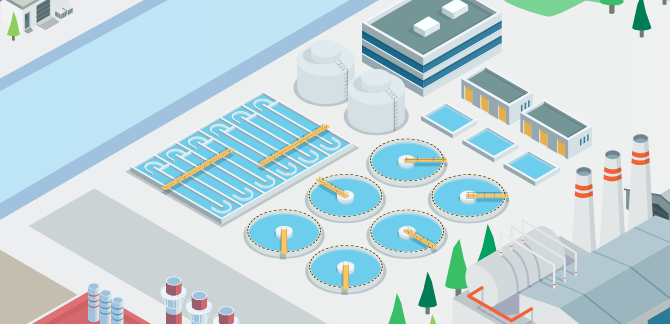

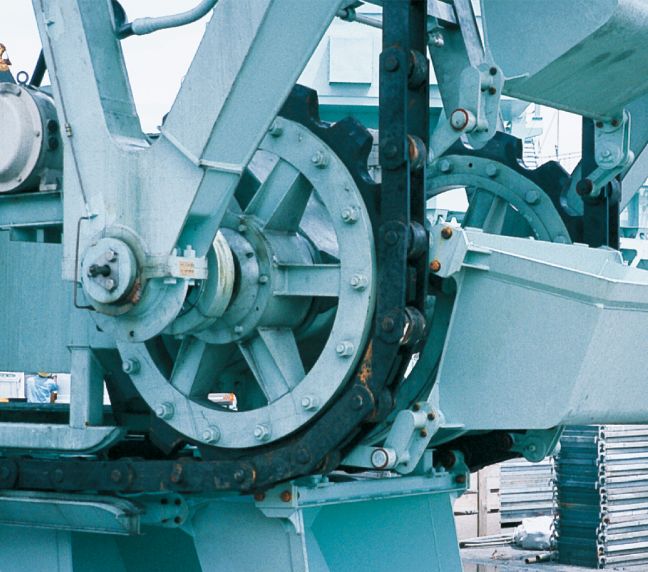

The “Industrial Chains” play a significant role in society by transmitting the power of motors and engines and safely transporting various goods. However, we do not often see them in our daily lives. Industrial chains are used for a wide variety of purposes in manufacturing processes in various fields, such as iron and steel, paper, and chemical plant, as well as in facilities such as sewage treatment plants and parking lot. Although the industrial chains are not placed particularly visibly, they drive society and the economy, supporting our lives and industry. Furthermore, there are many types of conveyors for transporting goods, and among them, chain conveyors have the advantage of demonstrating functionality in all kinds of applications and providing the flexibility to select any variation.

Chains support industries around the world.

“Strength” is required to continue working even in the harshest environment.

for use in wastewater and

sewage sludgeDurability

Sewage Treatment Plant

Sewage Treatment Plantto withstand heavy loadsToughness

Multi-story parking lot

Multi-story parking lotfor abrasion and

heat resistanceProductivity

Improvement

Steel Plant

Steel Plantit proves our reliability.Safety Confidence

Amusement Park

Amusement ParkWe have been striving to improve our products to fulfill our mission by

earning the trust of our customers through planning, design, analysis and research.

Our Products

As a comprehensive manufacturer of industrial chains, we can provide a variety of chains to move things in various situations.

Please scroll horizontally to see entire diagram.

Tap the icon.

02As a pioneer of the chain industry

Leading the future of chains by inheriting the DNA of pioneers

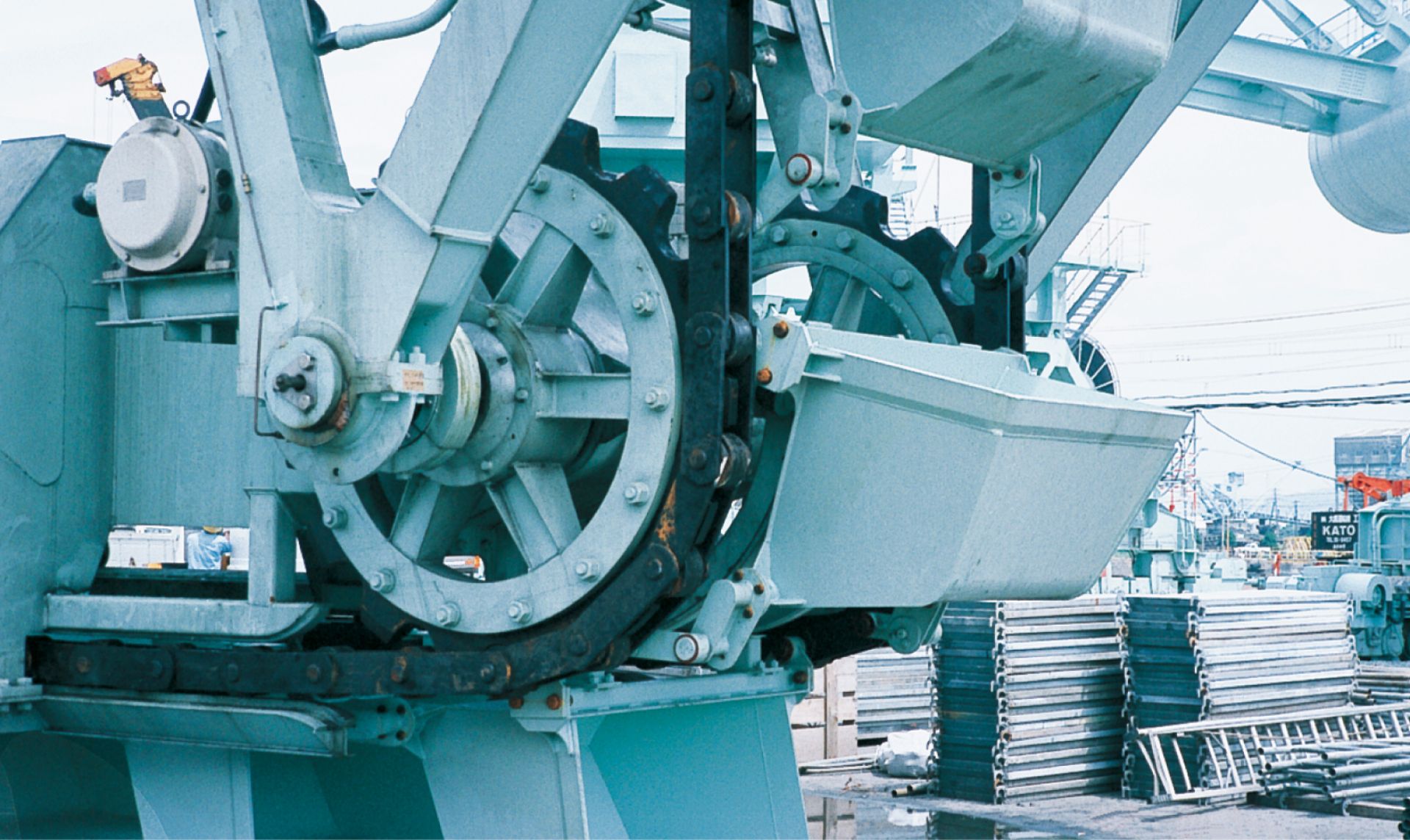

The history of chains in Japan dates back to 1910 when our predecessors, Tobata Casting Co., Ltd. started production of the first casting chain in Japan. In 1960, we began manufacturing and selling steel chains. After that, we moved our production base from Tobata Plant (in Kitakyushu City, Fukuoka Prefecture)to Kumagaya Plant (in Kumagaya City, Saitama Prefecture) ,currently called as Kanto Works of ZEXUS CHAIN Co., Ltd., and has been widely responding to the demand for chains in industrial society broadly providing continuous manufacturing processes including heat treatment, machining and assembly ,based on a rich experience and technology accumulated over 100 years since its establishment in 1910. Our DNA as pioneering chain manufacture has been succeeded to the present and as a pioneer in the industry and a comprehensive chain manufacturer, we will continue to create the future of chains with confidence and pride.

03Why Choose Us?

Quality based on the knowledge and expertise accumulated over more than 100 years

Our history originally started from manufacturing of Cast steel chains in Tobata, Kitakyushu and had shifted to the production of steel chains with globalization. Utilizing our strength and absolute confidence in our technology and handling technique related to steel, we have established quality trusted by many customers. Currently, we supply roller chains and conveyor chains, among them, water treatment chains used in sewage treatment plant have an industry-leading market share. In addition, our chains are used in other familiar applications such as escalator, large facilities that transport materials and products at steel plants, roller coasters at amusement parks, and lifts at ski resorts. We will continue to manufacture high-quality products based on knowledges and expertise accumulated over the decades.

Importance of “custom-made” service to meet diverse needs

We focus on “custom-made” services, where we plan, propose, and manufacture chains in accordance with the customer’s requirements. In manufacturing chains used in food plant, we don’t focus on functionality but also food hygiene and safety. Furthermore, we can flexibly meet the diverse needs of our clients carefully selecting suitable materials and thoroughly creating chains in accordance with their respective usage environments, such as shock resistance for facilities subjected to shock loads and corrosion resistance for facilities subjected to corrosive environments. We also provide orders for small-lot production. Although there are some concerns regarding higher unit prices for small-lot manufacturing services, we aim to reduce manufacturing costs through unique innovations such using common parts.

Business approach that accurately and promptly responds to detailed requests

We are committed to maintaining close communication with our clients on a regular basis, and make utmost efforts to accurately and promptly understand detailed requests for product improvements and so on. We value “responsiveness,” “swiftness,” and “flexibility” in our communication and constantly respond to inquiries from our clients in order to make exclusive and unique proposals for optimal specifications. Our goal is to make our clients feel that “ZEXUS CHAIN will certainly provide solutions.”

Building trust with clients through creativity and attention to detail

Thankfully, many of our clients continue to use our products, and one of the reasons is the high degree of customer’s satisfaction. Based on the close and deep communication with customers, we take into consideration the usage conditions and select the optimal specifications and provide meticulous support to ensure long and reliable use.

In the manufacturing process, we accurately communicate important points to clients, while preparing a precise drawing and confirming specifications in advance to ensure that there are no discrepancies with the client’s requirements. This kind of service is one of strengths of our company, which possesses our own factory. With our attention to details and the knowledge we have developed over the years, we will continue to strive to provide superior products in the future in order to meet the expectations and trust of customers.

Rigorous quality inspections to ensure safety and security

In order to provide stable and high quality products, we conduct rigorous quality inspections using various methods and equipment. Furthermore, we also conduct durability and abrasion resistance tests during in-house development and prototyping to contribute to future industries.

Chain trivia

Who create chain for the first time in the world?

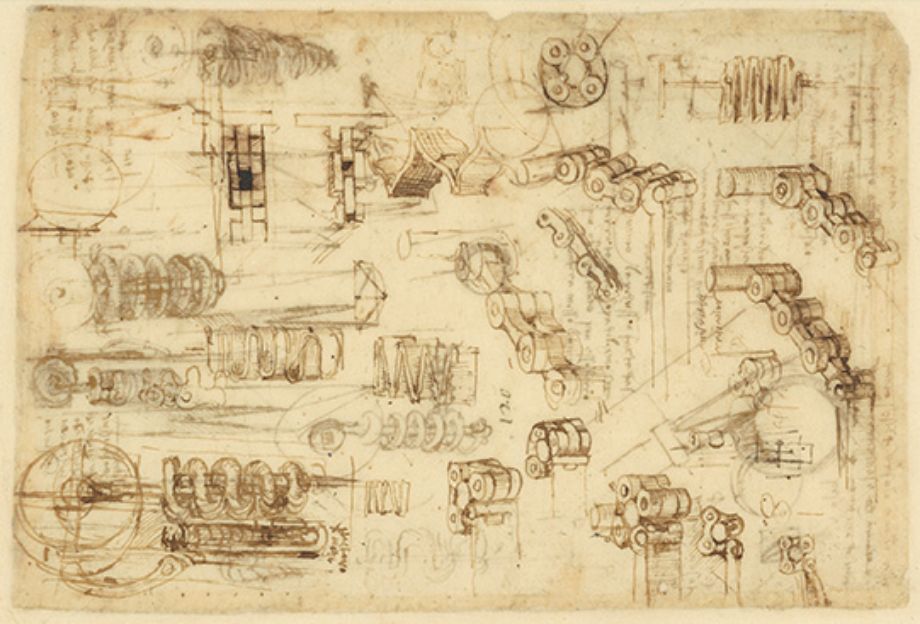

Sketch of a roller chain by Leonardo da Vinci

Sketch of a roller chain by Leonardo da VinciDo you know the origin of chain? It is said that Leonardo da Vinci ,who was an Italian polymath of the High Renaissance and famous as artist, painter, engineer, scientist and inventor, created “chain” for the first time in the world. His sketch showed image of chain and we know he had full of curiosity about chain. However there is no evidence that his ideas were ever created at this time.

After 300 years passed, in 18th century, with the development of steel and machine tool technologies through the industrial revolution, power transmission roller chains were crated for first practical application. French man Meduel Gal obtained a patent on the bicycle chain in 1832.

In 1903, the Wright Brothers, American inventors, achieved propelled flight with their “Wright Flyer,” which was driven by roller chains. This was the first step the people could fly by airplane and proved that it was possible for humans to fly.

(source: Japan Chain Association “History of Chain”)

Inheriting our predecessors’ passion and technology for chains, we will continue to lead the industry by developing chains that will support and move the industry toward the next 100 years.

04Our Policies

- Product Quality Policy

- By combining more than 100 years of tradition with new technologies, we will continue to create a high-quality products and grow together with our customers toward future continuously like as if CHAIN is linked together.

- Product Research and Development Policy

- Along with continuously developing new products, we will focus on improving them for any applications with our accumulated expertise and many years of experiences in order to solve each customer’s issues.