FAQs

What are the Tensile Strength, Average Ultimate Tensile Strength, Assured Tensile Strength and Maximum Allowable Load?

Roller chain

Tensile strength: The maximum load when the chain is pulled to the point of breaking.

Average Tensile Strength: the average value of tensile test results

Minimum Tensile Strength: The setting value from calculation in consideration of the dispersion in the quality of components based on Average Tensile Strength.

Maximum Allowable Load: The allowable limit of maximum load based in dynamic strength.

Conveyor chain

Tensile strength: The maximum load when the chain is pulled to the point of breaking.

Average Tensile Strength: The setting value from calculation of tensile strength by engineering design.

Assured Tensile Strength: The tensile strength that the manufacturer guarantees in transactions with the market in general, or with a specific user. It is generally set according to the minimum tensile strength, but may be determined in other ways in other circumstances.

CLOSE

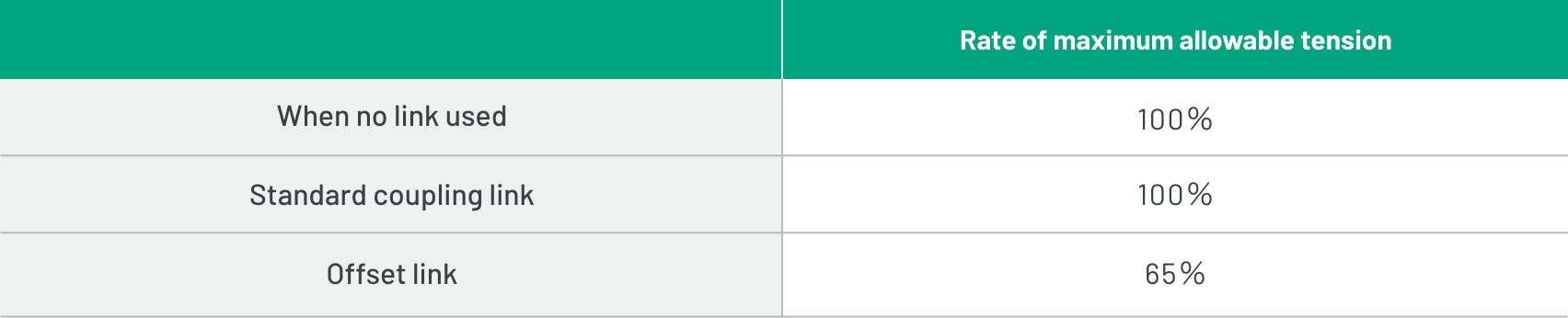

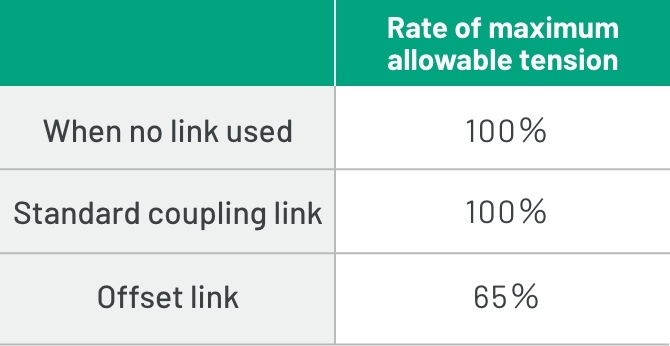

Does the allowable load change when using offset links on roller chain?

The maximum allowable chain tension when using offset links on roller chain decreases as shown below.

CLOSE

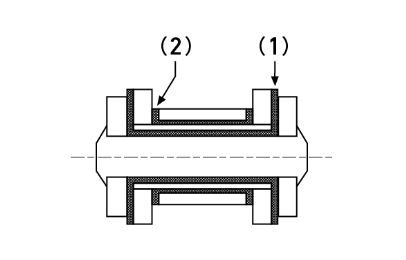

Where do you lubricate the chain?

There are two points crucial to the lubrication of roller chain, as indicated by numbers 1 and 2 in the diagram.

(1) Lubrication between pins and bushings Lubrication at this point prevents friction between pins and bushings, which are the main cause of roller chain wear.

(2) Lubrication at this point prevents friction between bushings and rollers, reduces noise, and absorbs impact load.

CLOSE

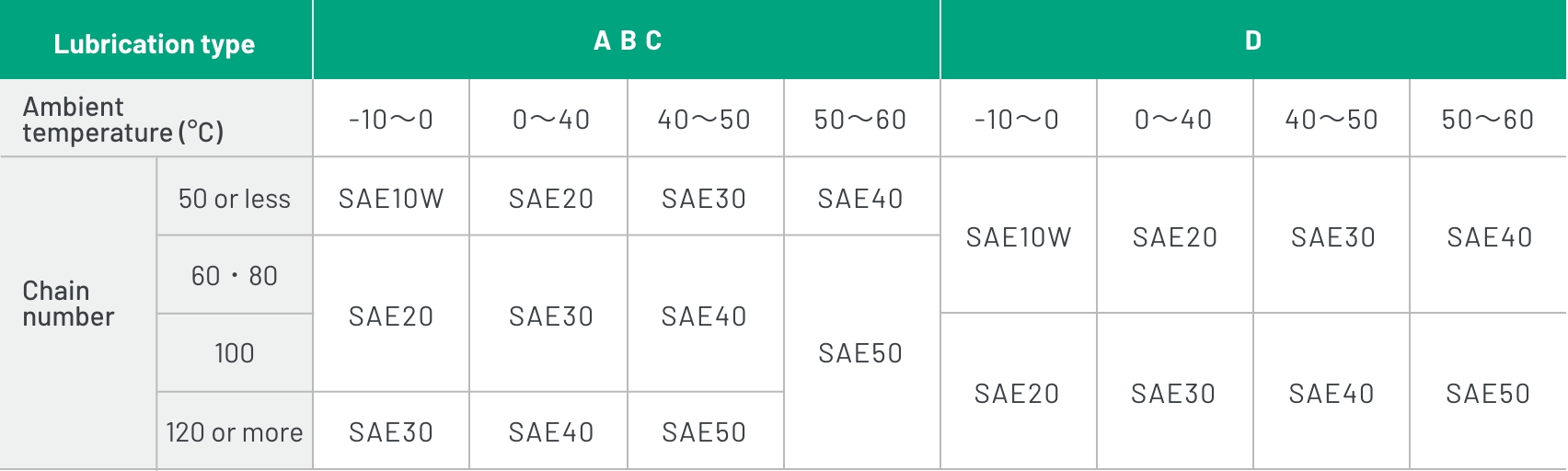

What is the better lubricant?

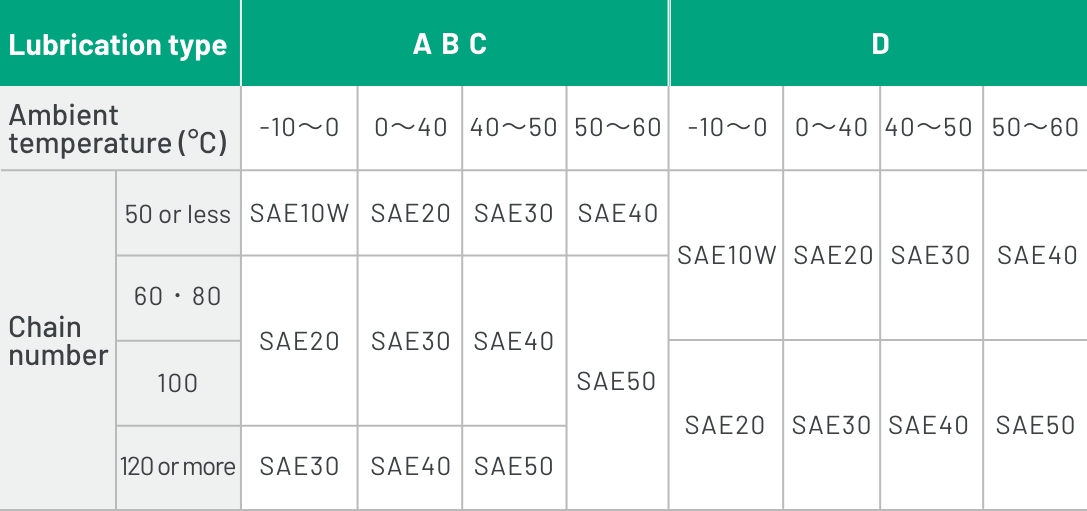

In general, use a high-grade industrial lubricant. Select a lubricant with appropriate viscosity according to the ambient temperature, lubrication type, and chain size from the table below.

Roller chains

Do not use waste oil as it may contain foreign matter, dust, or chips, or heavy oil or grease as they have a high viscosity and cannot penetrate the area between the pin and the bushing smoothly.

Lubrication Category A: Frequent manual lubrication with an oilcan or a brush

Lubrication Category B: Drip lubrication

Lubrication Category C: Oil bath or disc lubrication

Lubrication Category D: Pressure-fed lubrication with a filter, an oil cooler attached if necessary

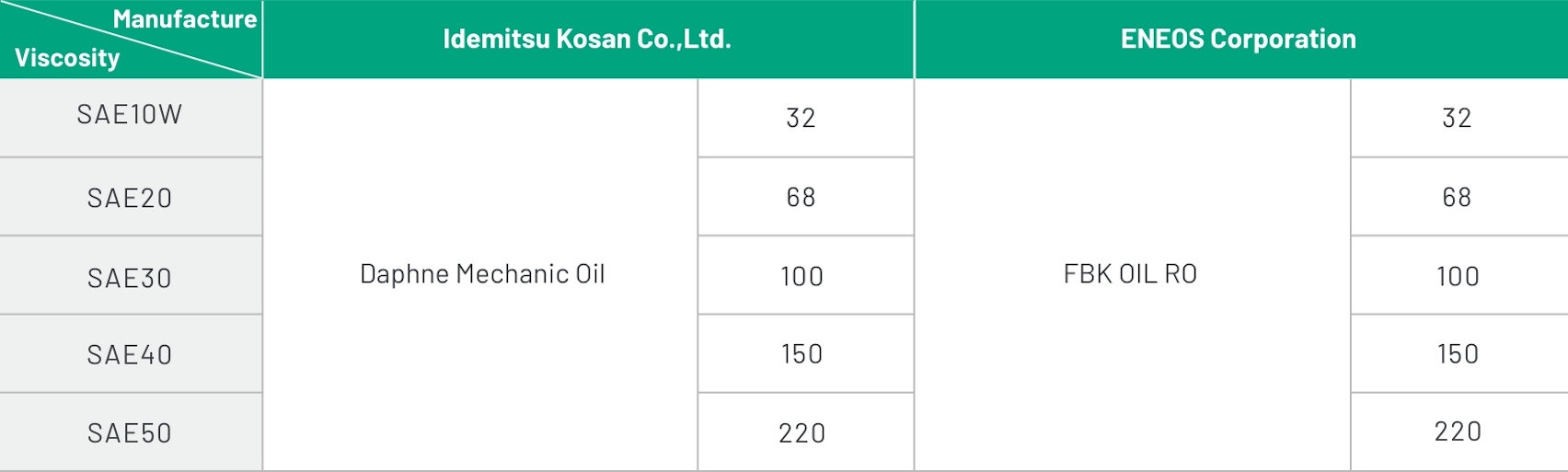

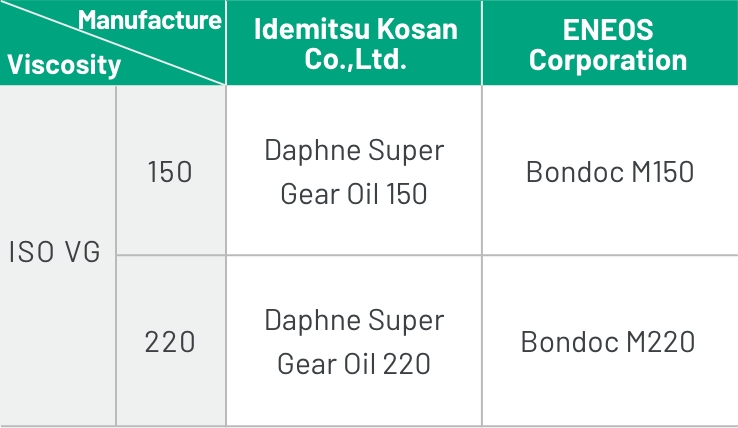

Commercial lubricating Oil (for reference)

Manufacturer name is in no particular order.

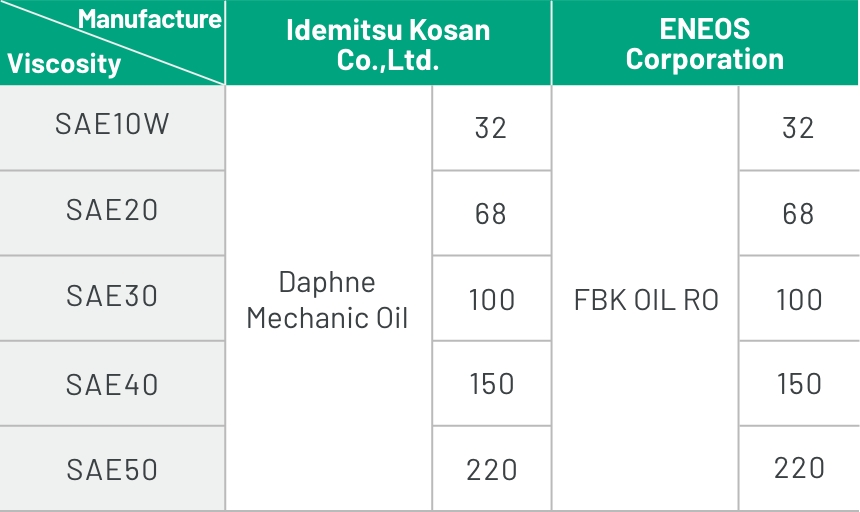

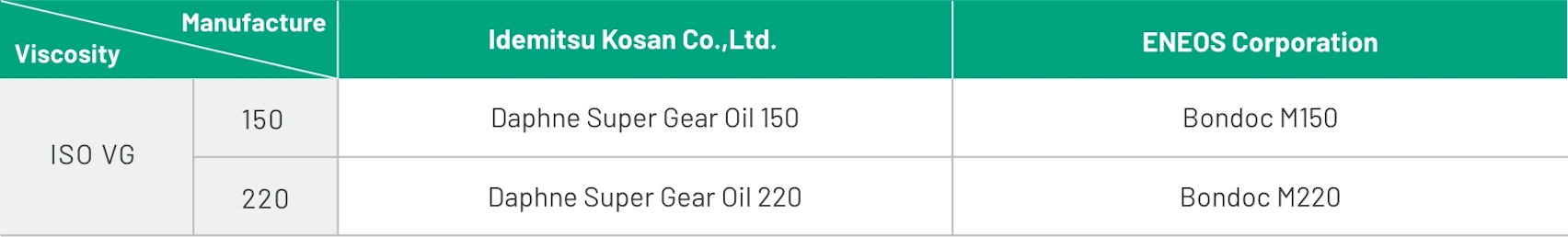

Conveyor chains

Commercial lubricating Oil (for reference)

Special lubricating oil is required when the ambient temperature is below 0°C or above 50°C. Also, depending on the usage environment, lubrication may not be possible.

In such cases, please contact us.

CLOSE

What components does chain comprise?

Conveyor chain comprises components such as link plates, pins, bushes and rollers. The example below is a standard conveyor chain.

- Link plate

- A flat, stamped component, with pin holes and bush holes formed by precision pressing.

- Roller

- May be made of cast iron, structural carbon steel or case-hardened steel, depending on the chain size.

- Bush

- Requires wear resistance, so bushes are made of case-hardened steel with surface hardening of the inner and outer surfaces.

- Pin

- Requires wear resistance and toughness, so carefully selected structural carbon steel is used.

CLOSE

What roller chain standards do you deal in?

We deal in a variety of standards, including JIS (Japanese Industrial Standards), ANSI (American National Standards Institute), and ISO (International Standards Organization).

CLOSE

Can you manufacture chain that is not in your catalogs?

What’s the difference between S-roller and R-roller double-pitch roller chain?

The difference is the outer diameter of the rollers used. The S-roller type uses smaller rollers, while the R-roller type uses larger rollers.

- Small roller series (S-roller type)

-

- The last digit in the chain’s numeric designation will be 0.

- This series has the same roller diameter (outer) as standard roller chain.

- Standard sprockets can be used if they have 30 or more teeth.

- Large roller series (R-roller type)

-

- The last digit in the chain’s numeric designation will be 2.

- This series has the same roller diameter (outer) as double-pitch roller chain.

- Specific sprockets must be used.

Reference: Dimensions of Double-Pitch Roller Chain for Conveyors

CLOSE

What is the working limit of the chain? And how do you inspect it?

Replacement guidelines are as follows.

- Roller chain

- Please see Chain/Sprockets > Roller Chain/Sprockets for Roller Chain.

- Conveyor chain

- Please see Chain/Sprockets > Conveyor Chain/Sprockets for Conveyor Chain.

Please refer to service manuals for more information on the inspection method.

CLOSE

What are the specifications of conveyor chain?

Our conveyor chain is classified as follows, according to the materials it is made of and its heat treatment.

Please see this PDF for more information.

CLOSE

Chain attachments

A variety of attachments are required, according to how the chain will be used.

See these PDF files for more information.

Main type of attachments for standard conveyor chain

Main type of attachments for steel conveyor chain

CLOSE

What is the standard length of roller chain?

Our roller chain is 10 feet (3,048 mm) long.

CLOSE